|

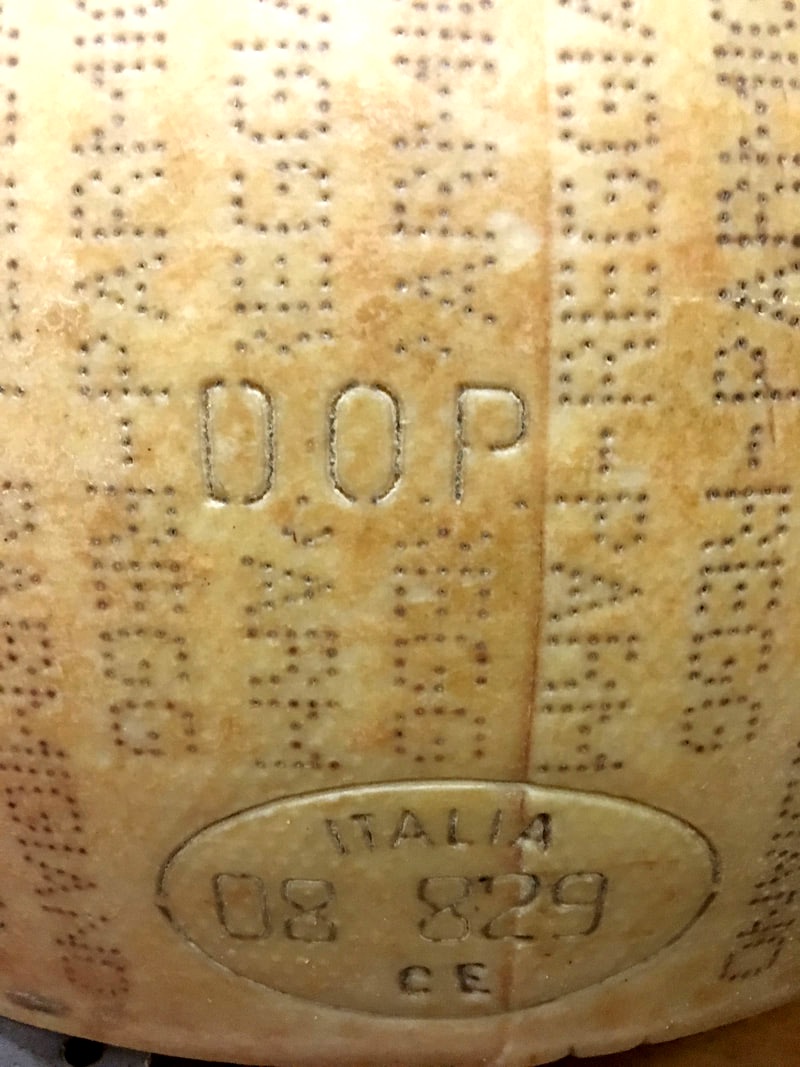

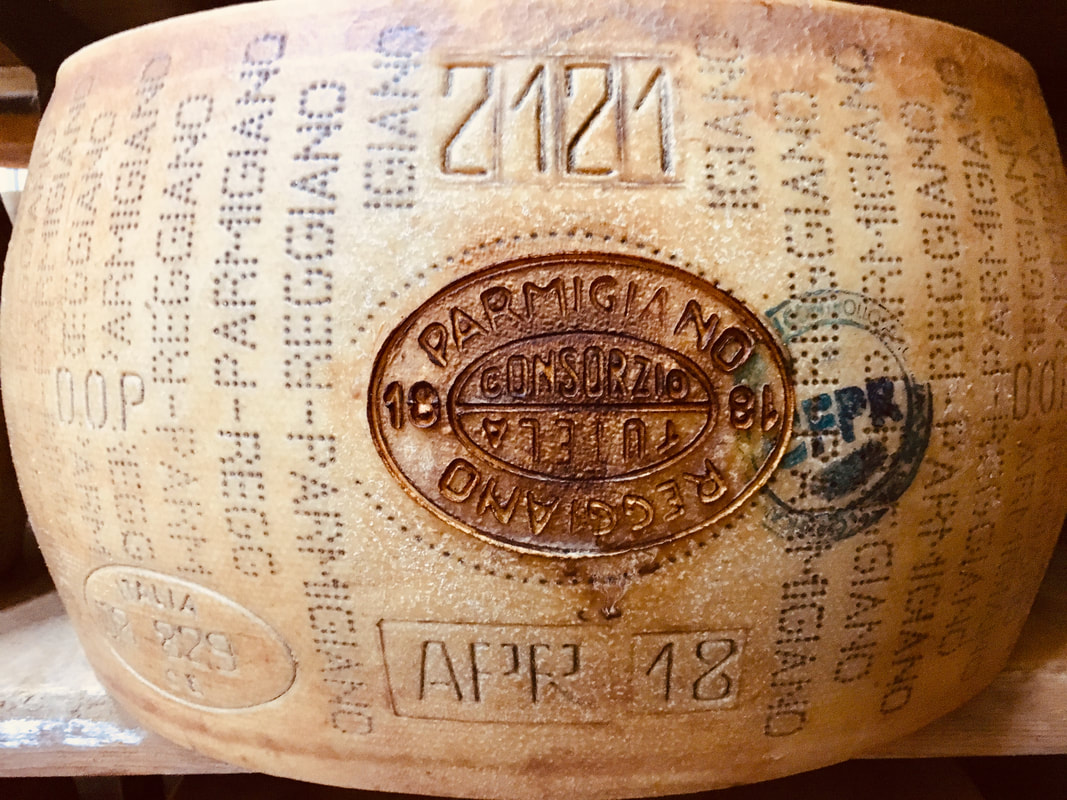

We recently had the pleasure of visiting the charming city of Parma, long renowned as a city of gastronomy, to see first-hand how Parmigiano Reggiano, one of the world’s most famous artisan cheeses beloved the world over for its distinct taste, is produced. Parmigiano Reggiano has been produced since the 1200s, first appearing in the Benedectine and Cistercian monasteries of Parma and Emilia Romagna. Today, this 100% natural cheese is still produced how it was then, using only three ingredients: milk (sourced from 3,000 farms across the region, produced from four different breeds of cows - Red Reggiana, Brown Cow, Modenese White Cow and Frisona), salt and rennet. Only a small selection of tools are used to process the cheese; a mixer (to mix the 520 litres of milk that go into every wheel), a spino (to break up the cheese into granules), and a wooden paddle (to raise the cheese from the bottom and extract it using muslin cloths). The cheese is aged for a minimum of 12 months, which allows it to develop its aromas and complexity. Parmigiano Reggiano is lactose free and packed with calcium, which makes it great for those whom are lactose intolerant but still want to reap the health benefits of dairy. The making of Parmigiano Reggiano Every day the master cheesemaker begins at dawn, when the milk from the morning milking arrives. The milk from the previous evening has been resting in steel tanks, resulting in natural separation, which thickens the milk, which is then skimmed. The milk is then poured into massive copper vats the size of hot tubs, where it slowly coagulates with the addition of rennet and whey. The milk is brought up to 55C to encourage curding and the cheesemaker then breaks up the curds, using a spino. The cheese that forms is wrapped in muslin and is hoisted out of the steel vats by two cheesemakers (given its heavy weight). I could see why all of the cheesemakers we saw during our visit were quite fit given the laborious nature of the job at hand! After the cheese is removed from the copper vats it is weighed down and put into a mold to give it its characterstic wheel shape. Afterwards, it’s moved to the maturation room where it matures to perfection (if only they had a room like this for husbands!) Only the best cheese gets the stamp of approval To ensure the utmost quality of every wheel of Parmigiano Reggiano, there is a protection body, The Parmigiano Reggiano Consortium, which includes all producers who process the milk into cheese. At 12 months, every wheel of cheese is quality tested and only if it passes stringent guidelines, will it be branded with its selection mark. Parmigiano Reggiano on EVERYTHING During our visit to Parma, we feasted at several fabulous restaurants, where we were treated to dinners featuring Parmigiano Reggiano in each and every course. Some of the dishes were quite inventive (Parmigiano Reggiano ice cream, anyone?) and we also enjoyed sampling three maturations of Parmigiano Reggiano paired with a selection of chutneys – a new addition to our cheeseboard next time we’re hosting a dinner party! Our favourite restaurants we dined at over the course of the weekend included: Les Caves, Antica Moka, Croce di Malta and Ristorante Inkiostro. Each restaurant had superb service and delicious traditional Italian cuisine, which combined made for a special experience. After learning about how much love and care goes into producing Parmigiano Reggiano, I have gained a newfound respect for it and for the people who pour their heart and souls into keeping the tradition of years bygone alive, making it taste even sweeter.

www.parmigianoreggiano.com www.parmacityofgastronomy.it Ashley Miln *During my visit I was hosted by the lovely teams at Parmigiano Reggiano, Antica Moca, Ristorante Inkiostro, Les Caves, Croce di Malta, and Grand Hotel de la Ville, Parma. All opinions and photography are my own.

0 Comments

Leave a Reply. |

Food and Drink products and features

Archives

May 2021

Categories

All

|

RSS Feed

RSS Feed